For 18 of these items, there was no data available except for the manufacturer`s recommendation. All of these were found to have shelf lives of 14 years to greater than 60 years, except for 19 items. A list of 70 representative materials was addressed in the program. Temperature is the main factor controlling shelf life however, atmospheric pressure, humidity, ultraviolet light, ozone and other atmospheric contaminants were also considered. An EPRI program was initiated more » to evaluate the methods used to assign shelf lives and to adapt the Arrhenius methodology, used in equipment qualification, to assign technically justifiable shelf lives. Many suppliers assign shelf lives based on product warranty considerations rather than actual product degradation. One safety-related equipment supplier was assigning a 10-year qualified life, from date of shipment, with no recognition of the difference in the aging rate in the plant vs. « lessĭiscussions with a number of Nuclear Utilities revealed that equipment qualified for 10 to 40 years in the harsh environment of the plant was being assigned shelf lives of only 5 to 10 years in the benign environment of the warehouse, and then the materials were being trashed. The above requirement reflects the primary role of design qualification to provide reasonable assurance that design- and age-related common failure modes will not occur during performance of safety function(s) under postulated service conditions. Inherent to design qualification is the requirement for demonstration, within limitations afforded by established technical state-of-the-art, that in-service aging throughout the qualified life established for the equipment will not degrade safety systems equipment from its original design condition to the point where it cannot perform its required safety function(s), upon demand. Design qualification is intended to demonstrate the capability of the equipment design to perform its safety function(s) over the expected range of normal, abnormal, design basis event, post design basis event, and in-service test conditions. This standard is for the design qualification section of the program only.

This is accomplished by a disciplined program of design qualification and quality more » assurance of design, production, installation, maintenance and surveillance. It is required that safety systems equipment in nuclear power generating stations meet or exceed its performance requirements throughout its installed life. Guidance for qualifying specific safety systems equipment may be found in various specific equipment qualification standards that are now available or are being prepared. It also establishes principles and procedures to be followed in preparing specific safety systems equipment standards. This standard is written to serve as a general standard for qualification of all types of safety systems equipment, mechanical and instrumentation as well as electrical. This paper briefly describes the IR and AMG processes and summarizes the unresolved technical issues identified through preparation of the documents. utilities were effective in preventing age-related degradation.

With a few noted exceptions, the AMG process indicated that current aging management practices of U.S.

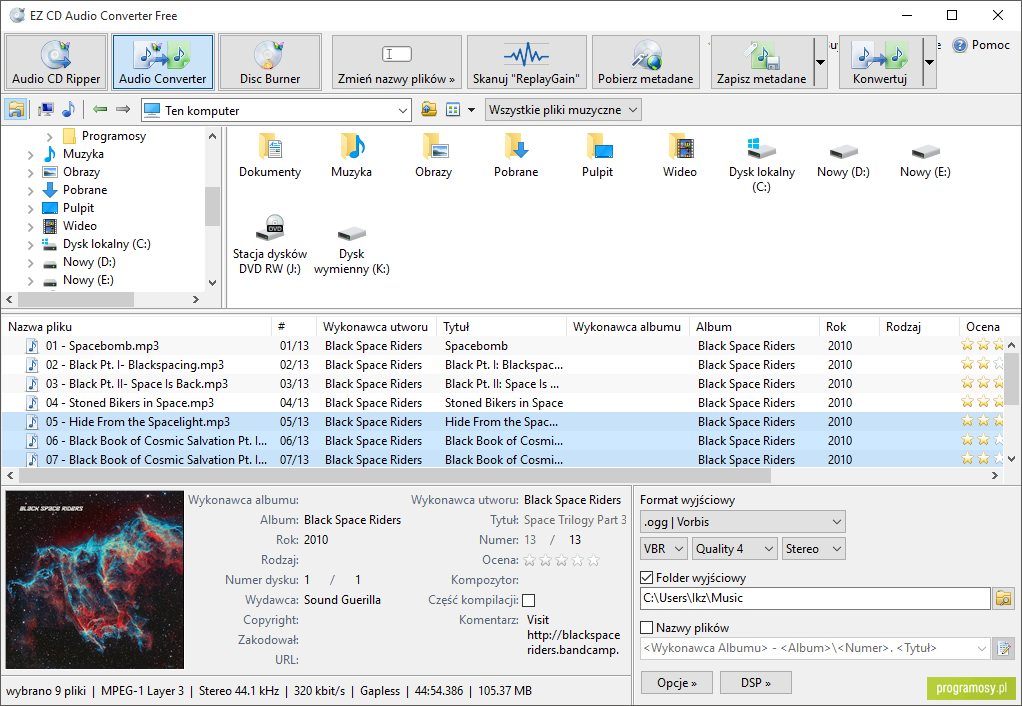

#CRACK EZ CD AUDIO CONVERTER 7.1.2.1 LICENSE#

The eventual use of AMGs in a future license renewal application will likely require NRC interaction at that time. Direct NRC interaction did not take place during preparation of individual AMGs due to their purely technical nature. Examples include certain issues related to fatigue, neutron irradiation embrittlement, intergranular stress corrosion cracking (IGSCC) and electrical cable equipment qualification.

0 kommentar(er)

0 kommentar(er)